As the core support of the modern textile industry, textile equipment covers the entire industrial chain from fiber processing to finished product manufacturing.

Image Source:Pexels

1. Functional matrix of core equipment

I.Spinning equipment: Precision conversion of fiber to yarn

Spinning equipment converts scattered fibers into uniform yarn through five core processes: opening, combing, drawing, roving, and spinning. Traditional ring spinning machines use magnetic suspension spindle technology to make the spinning speed exceed 20,000 rpm, which is 40% more efficient than earlier equipment. Rotor spinning machines achieve fiber cohesion through high-speed rotating rotors, and the production capacity of a single unit is 5 times that of conventional equipment, which is particularly suitable for short fiber processing. Jet spinning machines use compressed air to form spinning airflow, compressing the spinning process from 6 to 3, significantly reducing production costs.

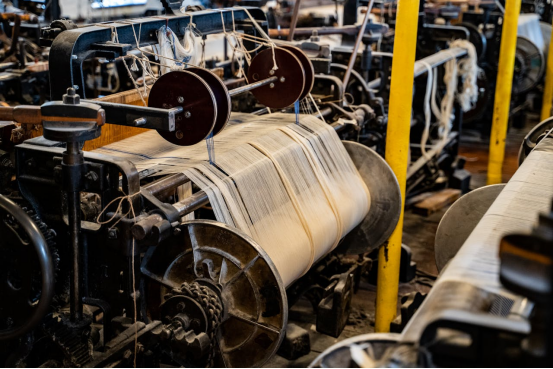

II.Weaving equipment: Intelligent control of warp and weft interweaving

Weaving equipment is divided into two categories: preparation machinery and looms. The warping machine uses a tension control system to evenly wind the warp yarn, the sizing machine uses high-pressure steam penetration technology to improve the yarn strength, and the warp drawing machine is equipped with a laser positioning system to achieve precise insertion of the warp stop sheet. Modern air jet looms are equipped with solenoid valve arrays, with a weft insertion accuracy of 0.01 seconds. With the electronic warp feeding device, the warp tension can be adjusted in real time to control the fabric density error within ±1%. The rapier loom transmits the weft yarn through a rigid rapier belt, which is particularly suitable for the production of heavy fabrics. Its weft selection mechanism supports 16-color weft yarn switching to meet the needs of complex pattern weaving.

III.Knitting equipment: innovative breakthroughs in three-dimensional weaving

Knitting equipment is divided into two major systems: warp knitting and weft knitting. The tricot warp knitting machine adopts multi-bar displacement technology, which can simultaneously control 48 bars on a weaving width of 3.3 meters to achieve precision weaving of 28 coils per centimeter. The Raschel warp knitting machine increases the number of weaving layers from single layer to three layers through a double needle bed structure, and is widely used in blankets, automotive interiors and other fields. The circular knitting machine is equipped with sinker triangle control technology, which can weave a variety of fabrics from fine to coarse needle gauges. Its active yarn feeding device reduces the horizontal stripe defects on the cloth by 80%.

2. Technical characteristics of modern equipment

I.High degree of automation and continuous production

Modern textile equipment generally adopts PLC control system to realize automatic connection of the whole process from raw material input to finished product packaging. The cleaning and combing unit integrates the cotton opening and combing processes to reduce manual intervention; the spinning machine and the automatic winding machine are directly connected through the conveyor belt to form a continuous production line. The German Trützschler carding machine adopts modular design and can complete the replacement of different fiber processing modules within 2 hours to meet the production needs of multiple raw materials such as cotton, chemical fiber, and wool.

II.Precision process parameter control

The air jet loom stabilizes the weft yarn flight speed at 30m/s through aerodynamic optimization, and cooperates with the electronic weft storage device to accurately measure the weft yarn length. The setting machine adopts an infrared temperature measurement system to control the oven temperature fluctuation within ±2℃, and cooperates with the overfeeding device to adjust the fabric weight to ensure the dimensional stability of the finished product. The dyeing machine is equipped with a flow meter and a pH sensor to realize the closed-loop control of dyes and auxiliaries, so that the color difference value ΔE is controlled within 0.8.

III.Intelligent monitoring and data analysis

The Internet of Things technology is deeply integrated into textile equipment. The QPRO expert system of Murata Machinery in Japan can monitor 72 spinning parameters in real time, predict the risk of breakage through big data analysis, and reduce the breakage rate from 15 times to 5 times per 10,000 spindles. The Italian Savio automatic winding machine is equipped with a 3D visual sensor, which can identify yarn defects with a diameter of 0.3mm. Combined with the AI algorithm, the defect classification is realized, and the yield rate is increased to 99.2%.

3. Technology-driven industry upgrade

I.Green manufacturing technology breakthrough

The GBART digital printing and dyeing technology developed by the Wanshili Group uses an AI algorithm to accurately calculate the amount of dye, making the dyeing rate close to 100%, eliminating the washing process and saving 99% of water. The German Monfushi setting machine adopts a heat recovery system to use the waste heat of exhaust gas to preheat the air intake, reducing the unit energy consumption by 35%. The spunlace nonwoven equipment optimizes the arrangement of high-pressure water needles to increase the fiber entanglement strength by 40% and reduce the use of chemical adhesives.

II.Innovation in flexible production models

The Rhino Intelligent Manufacturing Platform supported by Alibaba Cloud connects the equipment of 50 sweater companies through the Internet of Things to achieve dynamic order allocation. When receiving a small order of 100 pieces, the system automatically selects the three equipment with the lowest idle rate for combined production, and the delivery time is shortened from 15 days to 7 days. The 5G+AI quality inspection system deployed by Fujian Donglong Knitting has achieved an accuracy rate of 95% in the identification of warp knitted lace defects, and at the same time, it realizes real-time process adjustment through edge computing.

III.Expansion of new material applications

Carbon fiber reinforced plastics have begun to be used in textile machinery bearings, and their self-lubricating properties extend the equipment maintenance cycle by 3 times. Germany's Oerlikon nonwoven equipment uses nano-coating technology to make the filter material filtration accuracy exceed 100nm, which is widely used in the field of air purification. Bio-based polyester fiber production equipment uses enzymatic hydrolysis technology to convert plant straw into spinning raw materials, reducing carbon emissions by 60% compared with traditional processes.

The technological evolution of textile equipment has always revolved around the three cores of efficiency improvement, quality optimization, and environmental protection. From magnetic levitation spindles to AI visual inspection, from modular design to 5G interconnection, every technological breakthrough is reshaping the industry. When modern equipment reduces the number of workers required for spinning 10,000 spindles from 100 to 15, we see not only a leap in productivity, but also an inevitable path for the textile industry to transform from labor-intensive to technology-intensive.

- pre:Power equipment drives the energy arteries of modern society

- next:A New Chapter of Human-Machine Collaboration in Automatic Assembly Lines of Chinese Equipment Factories

Please click to consult us immediately or call the hotline: 4006-979-616We will solve the problems in your heart in detail。Online consultation