Hydrogen Energy Sector: Overcoming Manufacturing Challenges of Core Gas Turbine Components

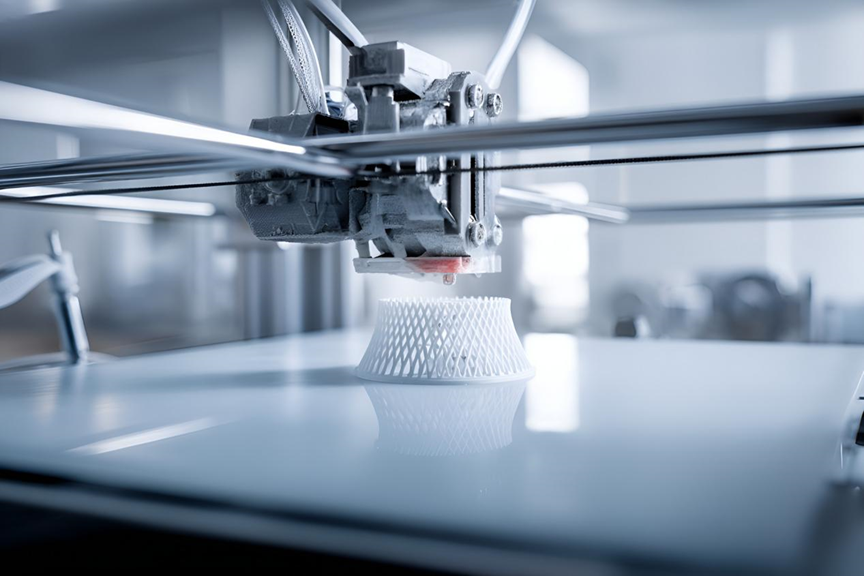

In the critical track of hydrogen energy industrialization, 3D printing technologies have emerged as a core technology to address the bottlenecks in the manufacturing of key equipment. As the central device for hydrogen power generation, pure hydrogen gas turbines face technical challenges such as "easy backfire, strong oscillation, and high emissions" in components like combustion chamber nozzles. Traditional precision machining struggles to meet the performance requirements under high-temperature and high-pressure conditions. Leveraging the advantage of integrated forming, 3D printing technologies enable the precise manufacturing of complex-structured components. Through the aerothermal design of micro-premixed combustion chambers and multiple rounds of simulation iterations, it has successfully overcome the three major technical difficulties in hydrogen combustion. To meet the requirement of components operating continuously at 850℃, the supporting high-temperature alloy materials, after precise laser energy control by 3D printing equipment, fully meet the high-temperature resistance standards. Furthermore, the uniform processing of thousands of micron-level holes on the flame tube wall and the integrated forming of nearly a thousand intertwined precision tubes have broken through the limitations of traditional processes, enabling the mass production of 30MW-class pure hydrogen gas turbines. A single unit can convert the annual curtailment of new energy projects with a capacity of one million kilowatts into over 100 million kWh of stable electricity.

Image Source:699pic.com

Petroleum Sector: Reconstructing Efficiency and Cost Logic in Model Manufacturing

In the intelligent transformation of the petroleum industry, the manufacturing efficiency of models such as pipeline pressure testing equipment directly affects the pace of technological iteration. 3D printing technologies have achieved a leap from "mold dependence" to "mold-free manufacturing" in this field. Traditional processes require 14 to 21 days to produce such complex models, with a maximum cost of 300,000 yuan per set. Moreover, design adjustments necessitate re-molding, which severely restricts innovation. Through millimeter-level data modeling and hierarchical process schemes, 3D printing technologies shorten the delivery cycle to 3 days and reduce costs by over 80%. Its core lies in replicating details such as pipeline routes and valve structures relying on 3D scanning technology. The main structure adopts stereolithography to ensure 0.05mm-level precision, while high-strength materials are used for linkage components to solve the brittleness issue. After post-processing such as isopropanol cleaning, multi-layer polishing, and UV curing, the model strength is increased by 50%, which can meet the needs of multiple scenarios including R&D verification, personnel training, and exhibition display, and has become an important support for the intelligent upgrading of oil and gas fields.

Wind Power Sector: Promoting the Upgrade of Blades towards Lightweight and Recyclable

The demand for large-scale and green development of wind power equipment is driving the in-depth application of 3D printing technologies in turbine blade manufacturing. Traditional wind power blades use thermosetting resin materials, which are not only heavy and have a long manufacturing cycle but also difficult to recycle after curing, failing to meet the requirements of green energy development. The combination of 3D printing technologies and thermoplastics provides an innovative solution to this problem. Thermoplastic materials can be recycled through thermal separation. Blade components are connected using thermal welding technology, replacing traditional expensive adhesives and further improving recyclability. With the design flexibility of 3D printing technologies, the R&D team embeds mesh structure cores with different densities between the blade surfaces, realizing the lightweight design of blades. It is expected to reduce weight and cost by more than 10% and shorten the production cycle by 15%. This technological innovation not only adapts to the manufacturing needs of ultra-long blades (over 100 meters in length) but also solves the environmental problems of traditional blades, providing support for the sustainable development of the wind energy industry.

Technology Integration: Building a New Ecosystem for Energy Manufacturing

The implementation of 3D printing technologies in the energy sector is not a single technological breakthrough but the formation of a complete ecosystem covering "material R&D, process optimization, and scenario adaptation". From the high-temperature alloys for hydrogen gas turbines to the thermoplastics for wind power blades, material innovation is deeply integrated with 3D printing processes, achieving a balance between performance and cost. On the production side, through software data control and precise equipment regulation, the problem of processing complex structures is solved, and the production cycle is shortened by an average of more than 60%. On the application side, its capabilities of small-batch customization and rapid iteration perfectly adapt to the diverse equipment needs in the energy transition. Such technical characteristics not only lower the R&D threshold for energy equipment but also promote the transformation of green manufacturing through efficient material utilization (reducing waste rate by 90%), providing solid technical support for the construction of a new power system and the achievement of the "dual carbon" goals, and serving as an important component of the new quality productive forces in the energy sector.

- pre:The Internet of Things is ushering in a new era of intelligence

- next:New energy drives the upgrading of manufacturing industry

Please click to consult us immediately or call the hotline: 4006-979-616We will solve the problems in your heart in detail。Online consultation