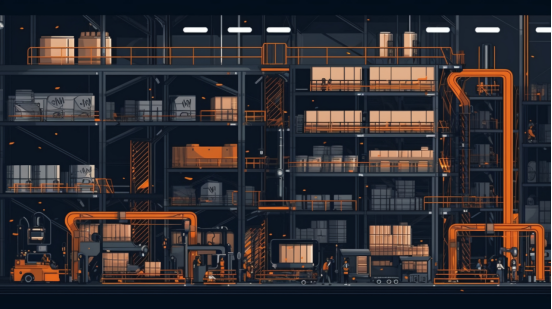

In today's fast-paced business and industrial environment, efficiency is the lifeline. Automatic loading and unloading equipment, as a key force in the field of modern logistics and industrial production, is changing the traditional loading and unloading operation mode in an unprecedented manner and becoming the core driving force for promoting efficient operation of various industries.

Image Source:699.com

Efficiency revolution in the field of logistics

In the logistics industry, the efficient circulation of goods is the key to ensuring the stability of the supply chain. The traditional manual loading and unloading method is not only inefficient and labor-intensive, but also prone to human errors, which result in damage to goods and delays. The advent of automatic loading and unloading equipment has completely reversed this situation. Take the stacker in the automated stereoscopic warehouse as an example. It can move quickly and accurately along the three-dimensional space track under the precise control of the computer system to complete the storage and retrieval tasks of goods. Compared with traditional manual operation, the stacker is not only faster, but also can work 24 hours a day, greatly improving the storage density and warehousing efficiency of the warehouse.

At the port terminal, the automatic loading and unloading bridge plays an irreplaceable role. These huge mechanical equipment can easily grab and move containers to achieve rapid loading and unloading of goods. Combined with the intelligent scheduling system, they can automatically plan the optimal loading and unloading plan according to the arrival time of the ship, the type and quantity of cargo, etc., reduce the ship's stay time in the port, and increase the port's throughput. According to statistics, ports equipped with automatic loading and unloading bridges can achieve several times higher cargo handling efficiency than traditional ports, thereby effectively promoting the development of global trade.

Solid backing for industrial production

In the field of industrial production, automatic loading and unloading equipment is also an important factor in ensuring the continuity and stability of production. In automobile manufacturing plants, the loading and unloading system composed of automated conveyor lines and robotic arms can accurately transport parts from warehouses to production lines and assemble them according to predetermined procedures. This highly automated loading and unloading method not only improves production efficiency, but also ensures the stability of product quality. Because in the entire loading and unloading and assembly process, the interference of human factors is minimized, reducing the damage to parts and assembly errors caused by improper operation.

In the chemical, food and other industries, automatic loading and unloading equipment also plays an important role. For example, in chemical companies, automatic loading and unloading equipment can safely and efficiently complete the loading and unloading of hazardous chemicals, avoiding the safety risks that may be caused by manual operation. In food processing plants, automated packaging and loading and unloading equipment can ensure the hygiene and safety of food during loading and unloading, and improve the quality and shelf life of products.

Broad prospects for future development

With the continuous advancement of science and technology, automatic loading and unloading equipment is developing in a more intelligent, flexible and green direction. The application of technologies such as artificial intelligence, the Internet of Things, and big data enables automatic loading and unloading equipment to have the ability to self-learn and self-optimize, and can automatically adjust working parameters and operating modes according to different operating environments and task requirements to achieve more efficient and accurate loading and unloading operations.

At the same time, in order to adapt to the needs of different industries and scenarios, automatic loading and unloading equipment is also constantly innovating and improving to improve its flexibility and adaptability. For example, some new automatic loading and unloading robots can flexibly adapt to goods of different shapes and sizes, and realize rapid switching of multiple loading and unloading tasks.

In addition, the enhancement of environmental awareness has also prompted automatic loading and unloading equipment to pay more attention to energy conservation and emission reduction in design, adopt more environmentally friendly materials and energy, and reduce the impact on the environment.

Automatic loading and unloading equipment has become an indispensable and important part of the logistics and industrial fields. It not only improves the efficiency and quality of loading and unloading operations, reduces labor costs and safety risks, but also provides strong support for the sustainable development of various industries.

- pre:The heat pump industry is accelerating its breakthrough amid technological innovation and policy support

- next:The Development Trajectory and Diverse Applications of Packaging Machines Since Entering China

Please click to consult us immediately or call the hotline: 4006-979-616We will solve the problems in your heart in detail。Online consultation